Our Products in Motion:

The long, sustainable life of a railcar

Freight railcars are designed to operate for up to 50 years and then be recycled at the end of their useful life. This makes railcars among the most reusable and recyclable types of capital equipment on the planet.

Raw material sourcing

The most intense energy usage occurs at the beginning when steel is manufactured for its construction. This energy utilization results in a railcar with a low-emissions profile and longevity stretching multiple decades.

Manufacturing

A railcar also results in the creation of many jobs during its lifecycle, including the manufacturing process. Our direct employment model ensures nearly all production employees work directly for Greenbrier, allowing for full workforce integration.

Sale and Use

Customers include Class I railroads as well as

preeminent operating lessors, shippers and financial institutions. Rail is among the most efficient modes of surface transportation. Rail shipments move one ton of cargo 472 miles on a single gallon of fuel. By comparison, trucks carry cargo only 145 miles per gallon.

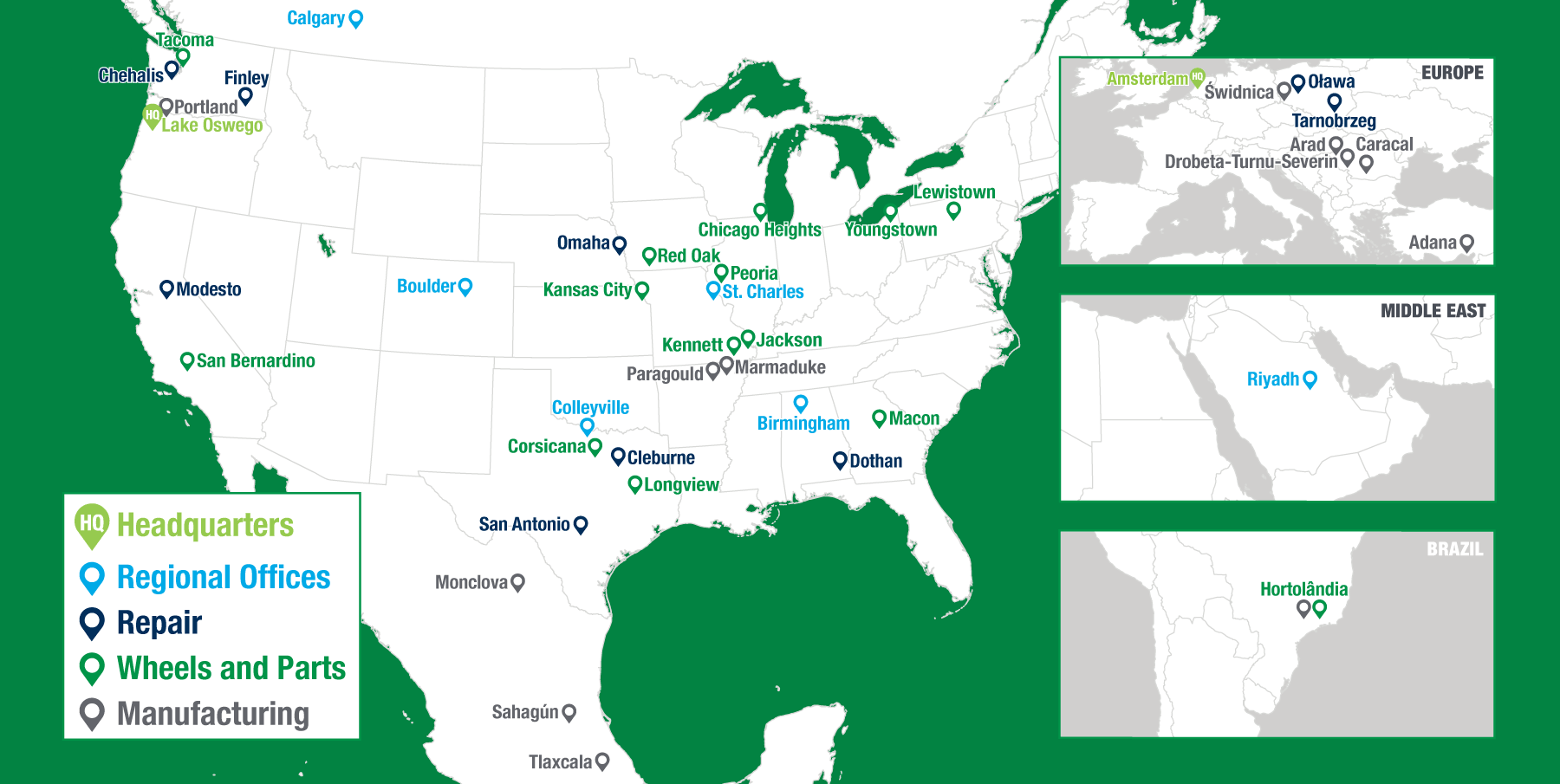

Wheels, Repair & Parts

Railcar repair and maintenance is critical in extending its useful life. Greenbrier Rail Services (GRS) offers signature after-market railcar services including replacement wheel sets, parts and general repair.

End of Life

Finally, after 30–50 years of operation, railcars are scrapped. Steel materials are simple to recycle, melt down and repurpose into a new railcar or other steel-based products.

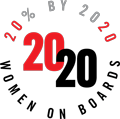

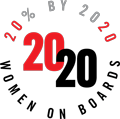

Board of Directors

Greenbrier’s Board of Directors is focused on strong leadership and sound governance practices. Our Board is responsive to a continually evolving business landscape, including overseeing Greenbrier’s response to the COVID-19 pandemic.

Greenbrier retains a high level of diversity with 30% female Board representation. In 2019, we were recognized as a “winning” company by 2020

Women on Boards (WOB). WOB is a nonprofit with the mission of empowering female business leaders and improving diversity and inclusion at the board level.

Board Demographics:

Our Board is keenly focused on diversity throughout Greenbrier as part of our companywide talent development initiative, including candidates for the Board, executive roles and other senior managers.

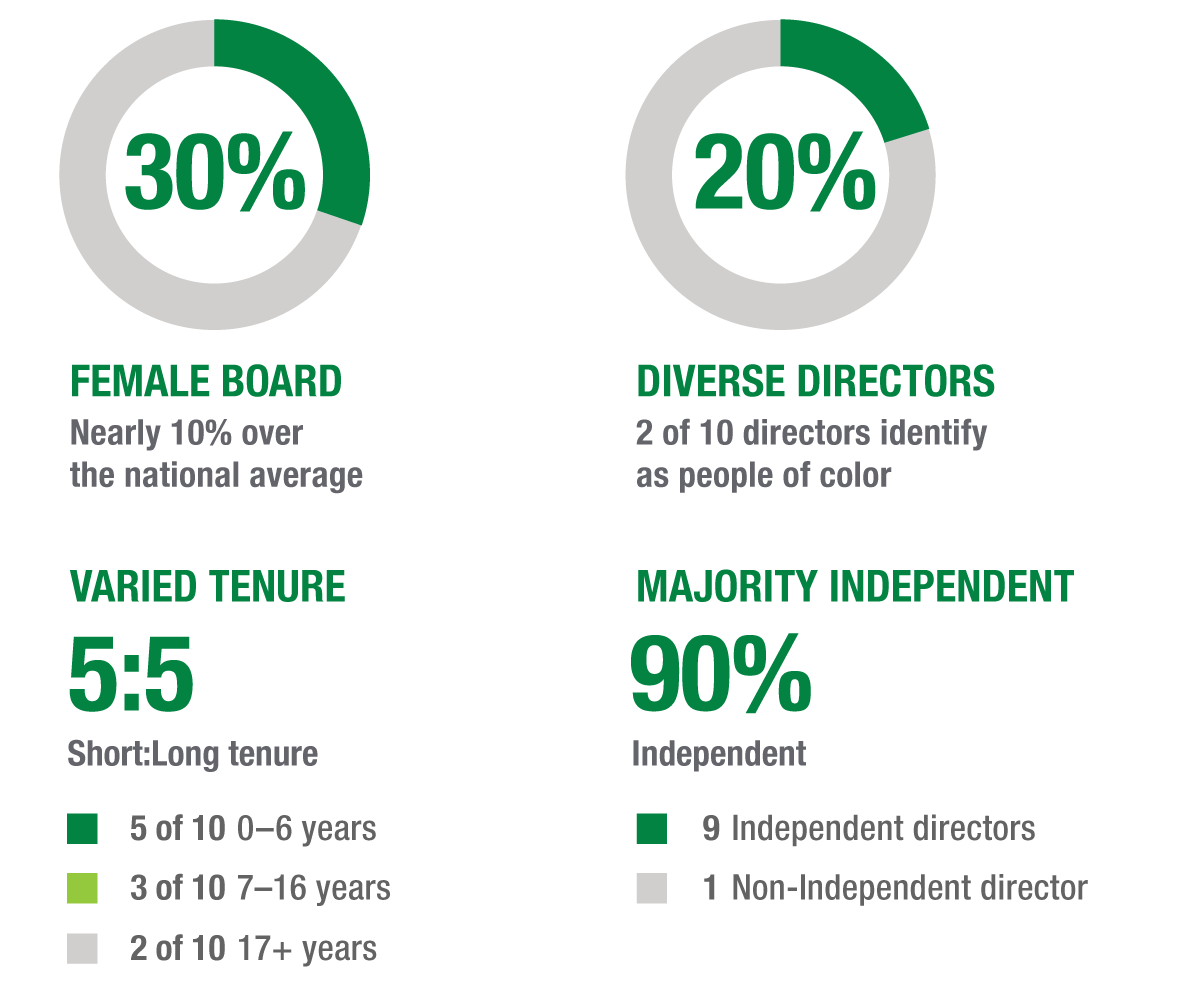

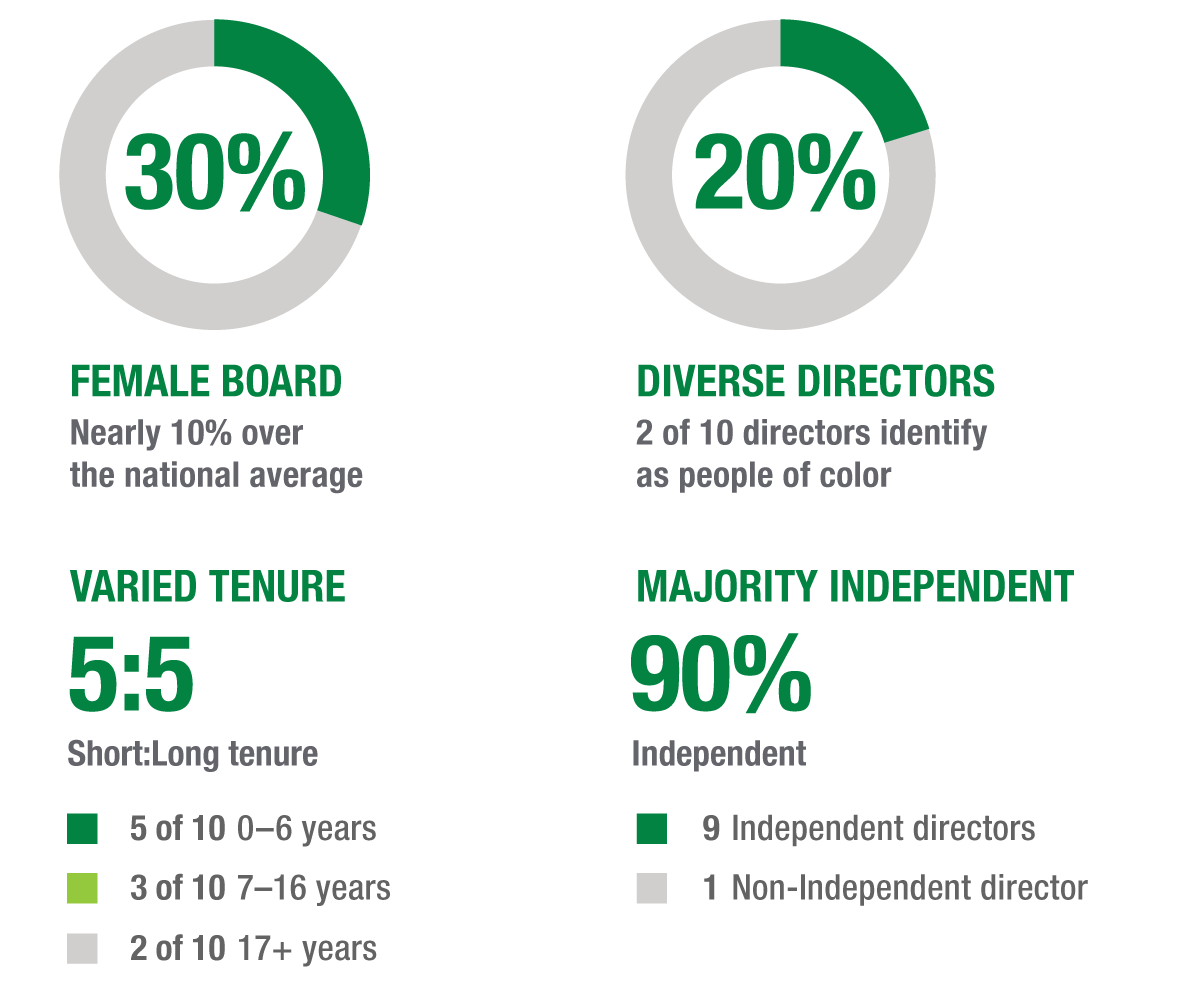

Personal Safety

Safety Performance

To monitor our performance, we track multiple safety metrics. We analyze the causes of injuries, first-aid events and near-misses. We have improved over time by reducing the number of injuries and the severity of those injuries.

We multiply the effectiveness of our safety improvement program by involving everyone, from our CEO to each new hourly employee. We audit our workplaces every day, with our daily aim focused on zero unsafe behaviors and zero workplace risks.

Diversity & Inclusion

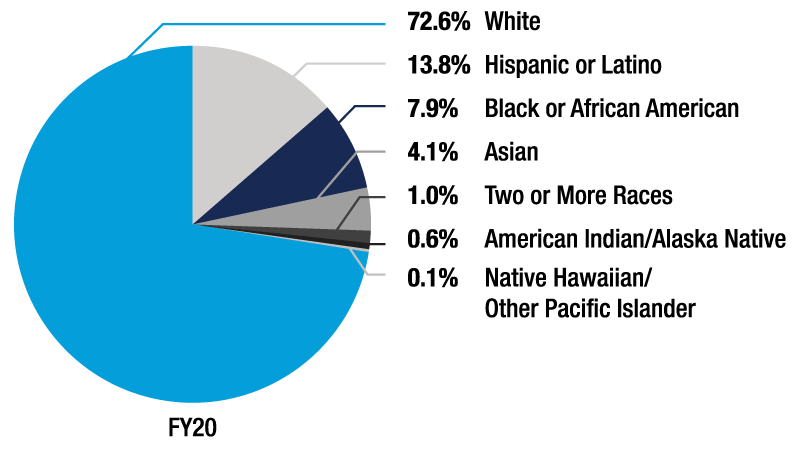

We believe in having a robust diversity, equity and inclusion culture that prioritizes a welcoming, supportive and inspiring atmosphere where people of different races, ethnicities, genders and sexual orientations can flourish.

Greenbrier remains active in a variety of employer diversity organizations. An example of diversity at Greenbrier exists within our senior commercial team, who promote, market and sell our products. The team is 30% female and 20% racially or ethnically diverse.

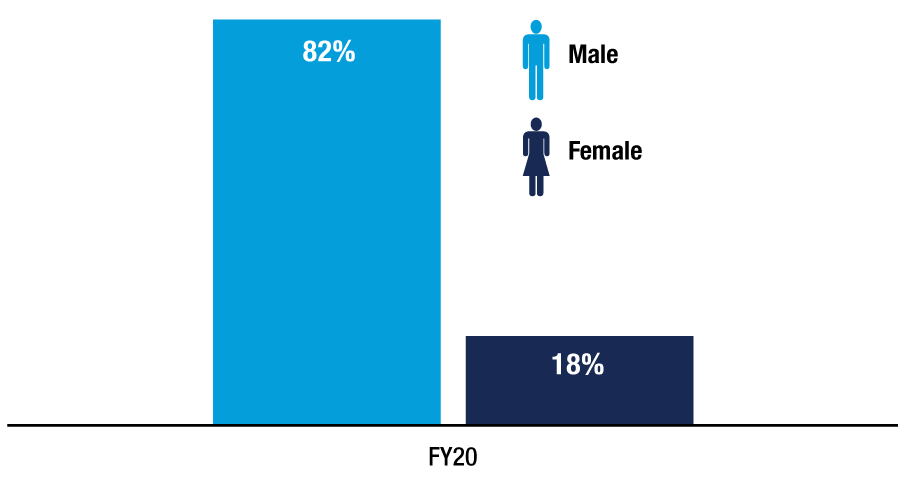

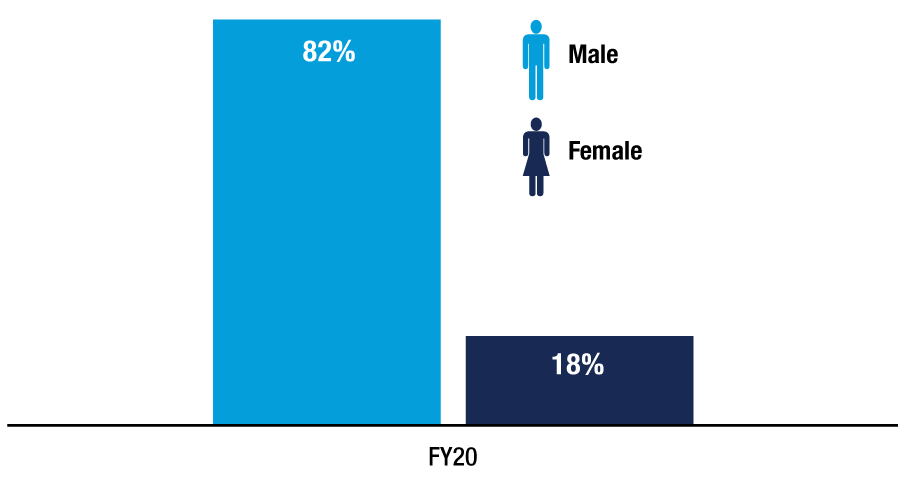

Diversity Statistics of Active U.S. Employees

GENDER DIVERSITY

ETHNIC DIVERSITY

Greenbrier is committed to improving our environmental performance, both by reducing our environmental footprint and by meeting or exceeding the ecological requirements in the countries where we operate.

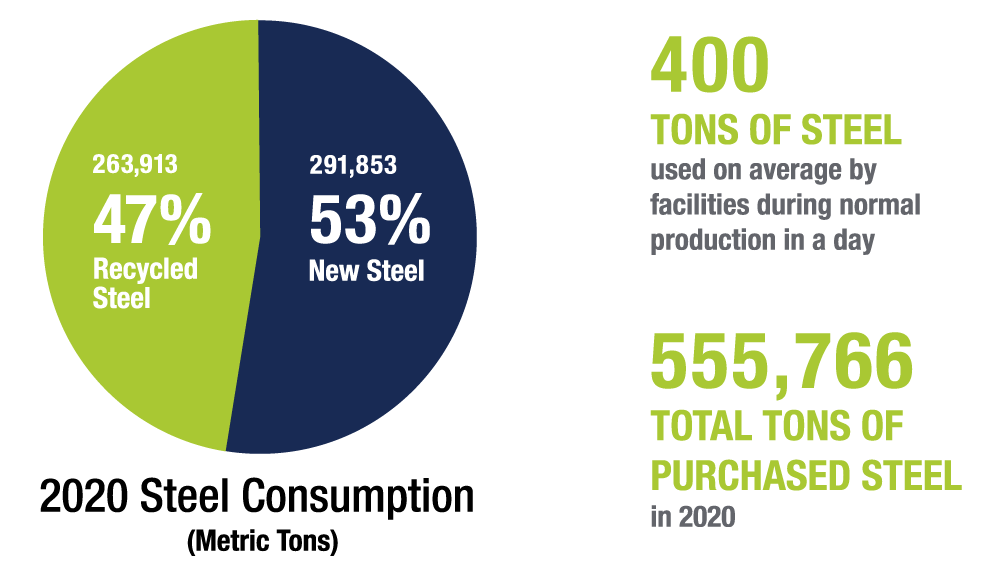

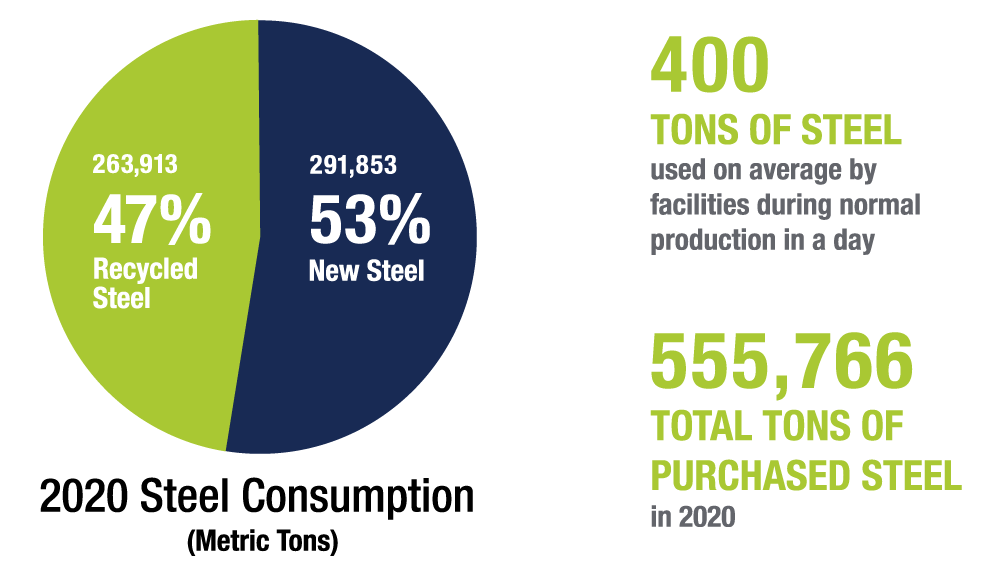

Natural Resource Utilization

Railcar manufacturing uses large quantities of steel. This makes natural resource utilization one of Greenbrier’s most substantial environmental impacts.

Our Goals:

• For 2021, to track our actual recycled steel content for our material as supplied.

• Our long-term goal is to increase steel use efficiency.

CASE STUDY:

Southwest Steel / Corsicana Partnership

An Unexpected Merger Synergy

Greenbrier owns multiple facilities in Texas, including Greenbrier

Corsicana, a Wheels shop, and Southwest Steel Casting

Company, a steel fabricator for railcar components, formerly an ARI

Company. These shops are neighbors. When Greenbrier completed

the ARI asset acquisition in July 2019, both facilities came under the

Greenbrier umbrella and the potential for collaboration expanded.

Southwest Steel has seen many benefits since this partnership

began, the most significant is that they purchase old wheel sets from

Corsicana to melt into brand new casting components. This effort

not only provides Corsicana a consistent market for recycling its

wheel sets, but Southwest Steel now uses 100% recycled railcar

material to produce castings. Receiving truckloads of whole

scrap wheels directly from Corsicana has dramatically lowered

melting material costs, improved physical safety for its employees

and reduced the environmental footprint at both facilities.

Steel casting quality has also benefitted. This results from the

density of the wheels, which allows an entire scrap charge to go into

the furnace, creating a continuous melt start to finish. This makes a

cleaner, less oxidized steel, reducing the chance of internal defects.

Southwest Steel’s electrical kilowatt-hour consumption has

significantly diminished since the partnership began and has reduced its carbon usage during steel manufacturing to zero.

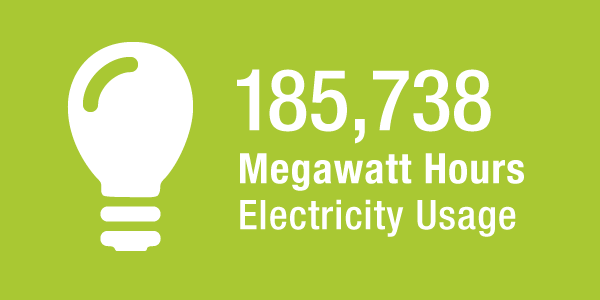

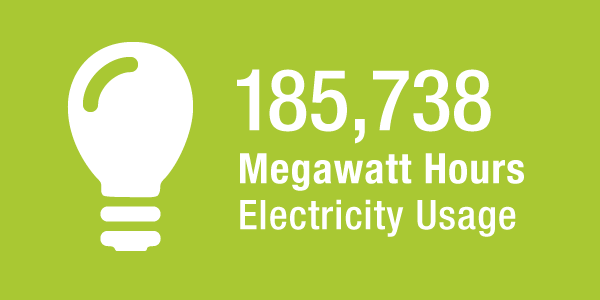

Energy Usage

Energy usage is an important measure to track Greenbrier’s environmental impact. Specifically, tracking the embedded energy in our supplied steel and measuring the energy utilization at our manufacturing facilities is the best opportunity to reduce our impact on the environment.

Our Goal

For 2021, measure the energy used per unit of production, which will allow us to understand how much we’ve improved our energy efficiency.

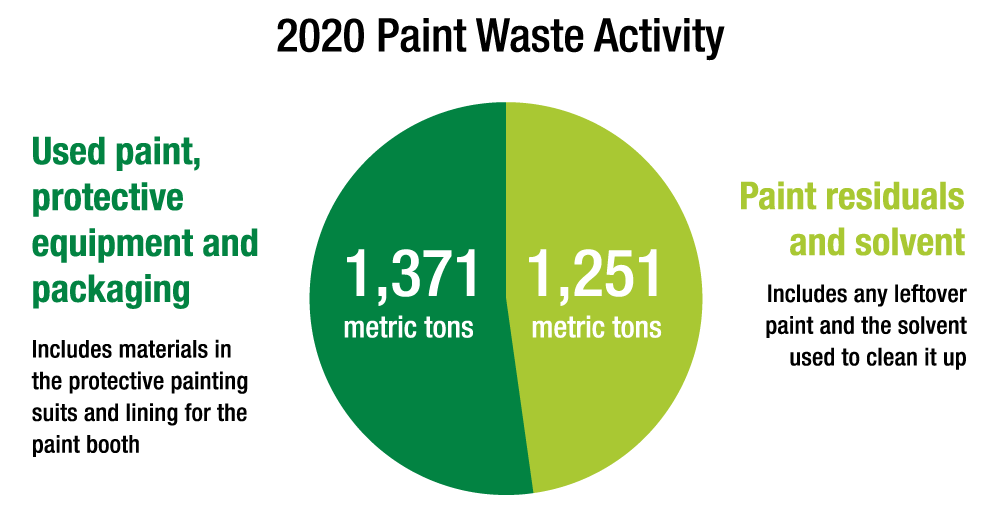

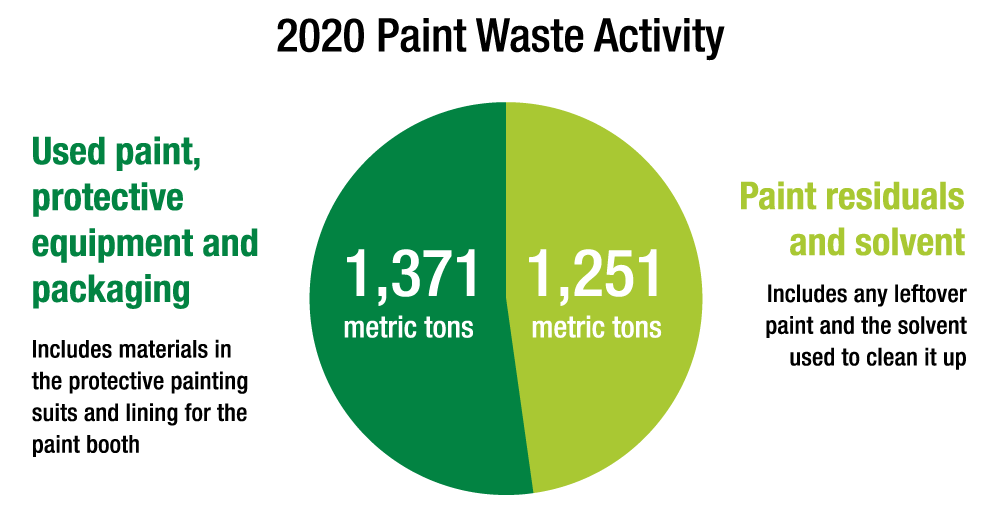

Hazardous Waste Management

Greenbrier works to reduce the amount of hazardous waste generated over time. We substitute less toxic material in our manufacturing process as it becomes available.

Reducing paint waste has the highest potential to benefit the environment.

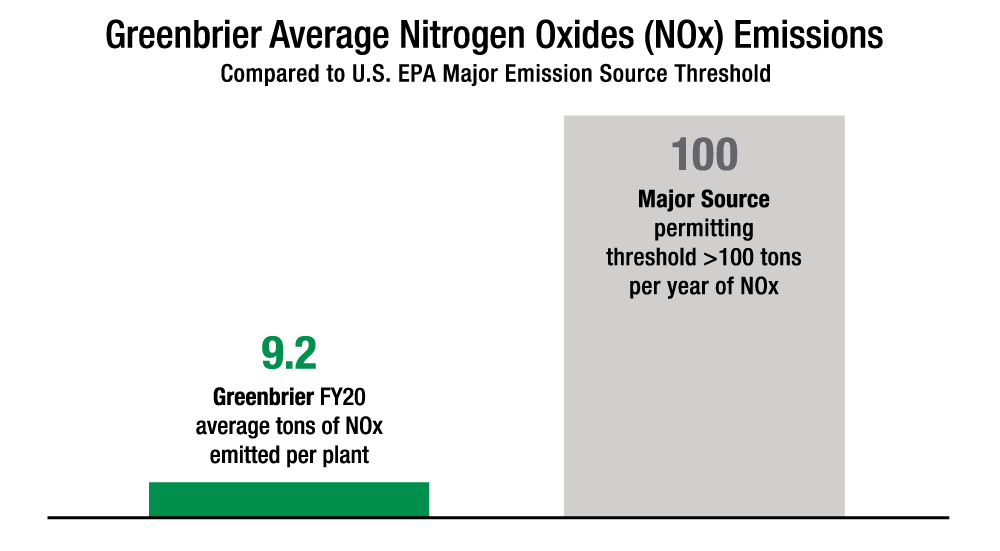

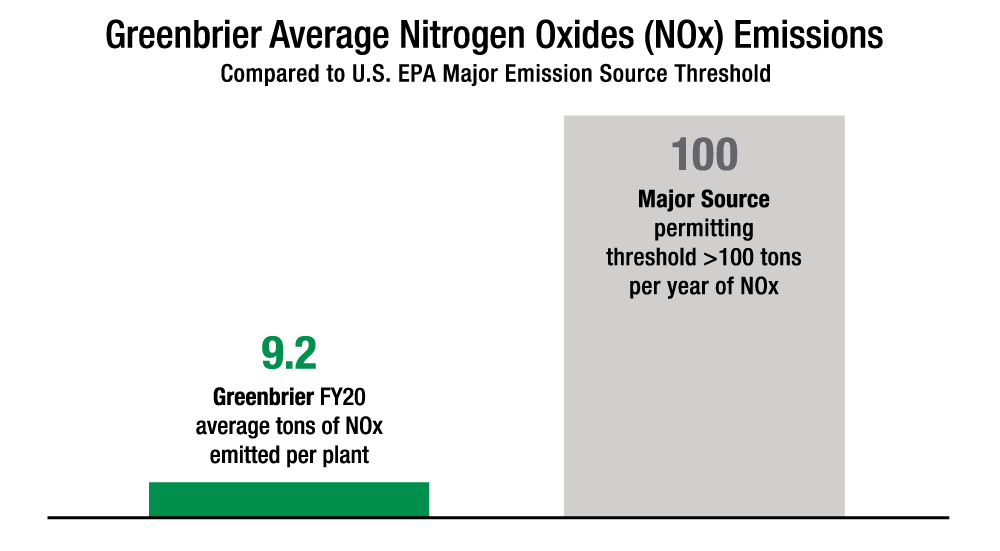

Air Pollutants

Greenbrier’s actual daily emissions are at extremely low concentrations and have minimal impact on the environment.

The majority of the air emissions at Greenbrier come from painting operations.

Greenbrier average NOx emissions <1/10 of EPA's size of a Major Source.

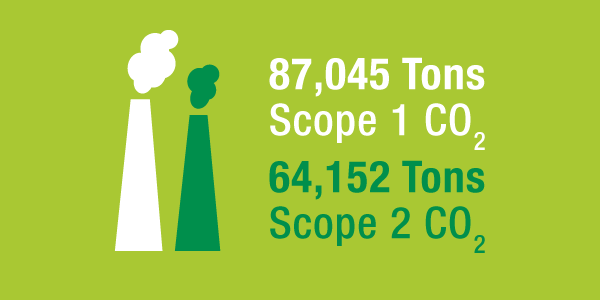

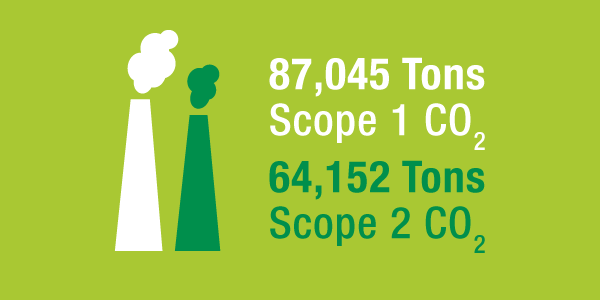

Greenhouse Gas (GHG) Emissions

Climate change is one of the most significant environmental issues facing society.At Greenbrier, we track our Scope 1 and Scope 2 GHG emissions at production facilities. Scope 1 (direct) emissions come from sources that the company owns or controls, such as business travel in a company car or the combustion of fuel in boilers and furnaces. Natural gas, diesel, gasoline, and propane are the main components of Greenbrier’s Scope 1 emissions. Scope 2 (indirect) emissions result from a company’s activities but from sources owned or controlled by another company.

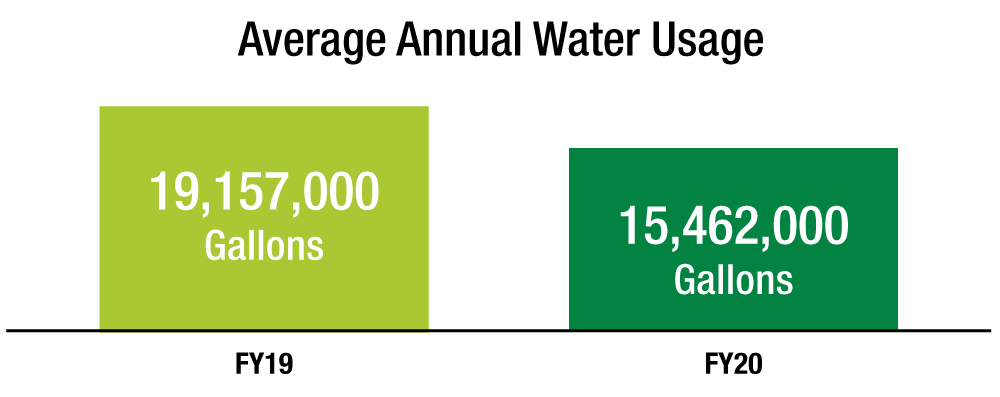

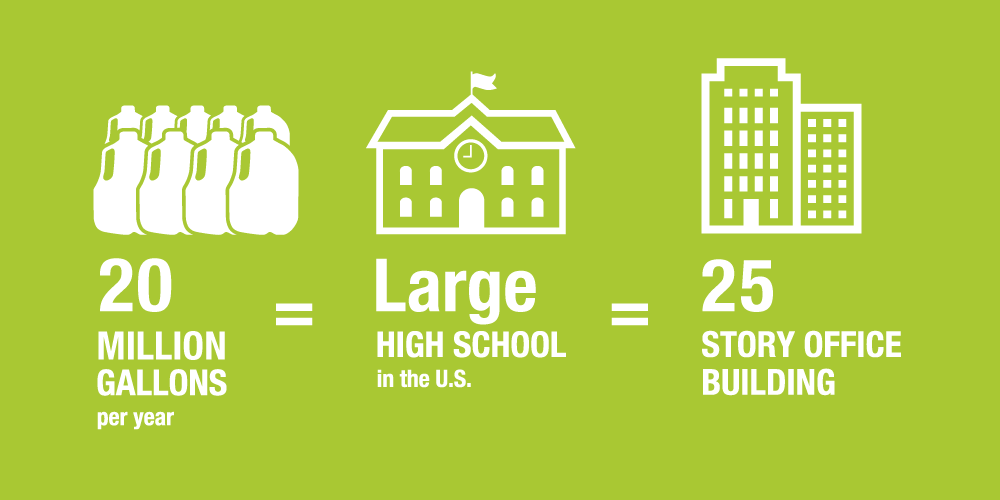

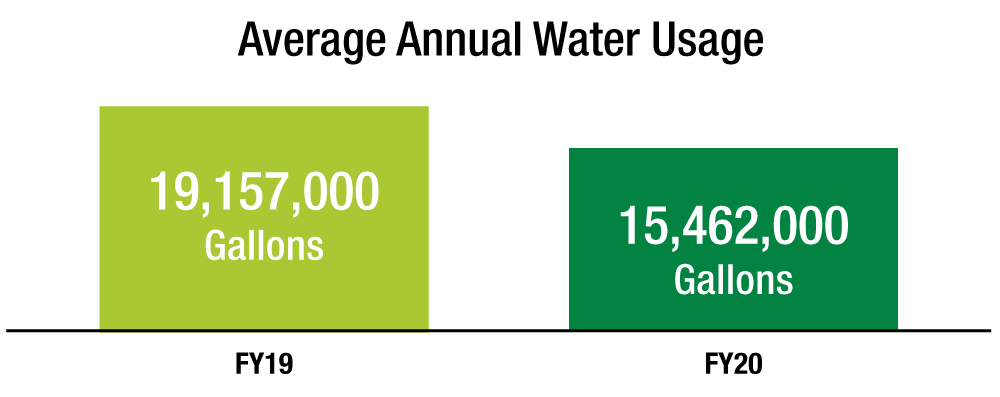

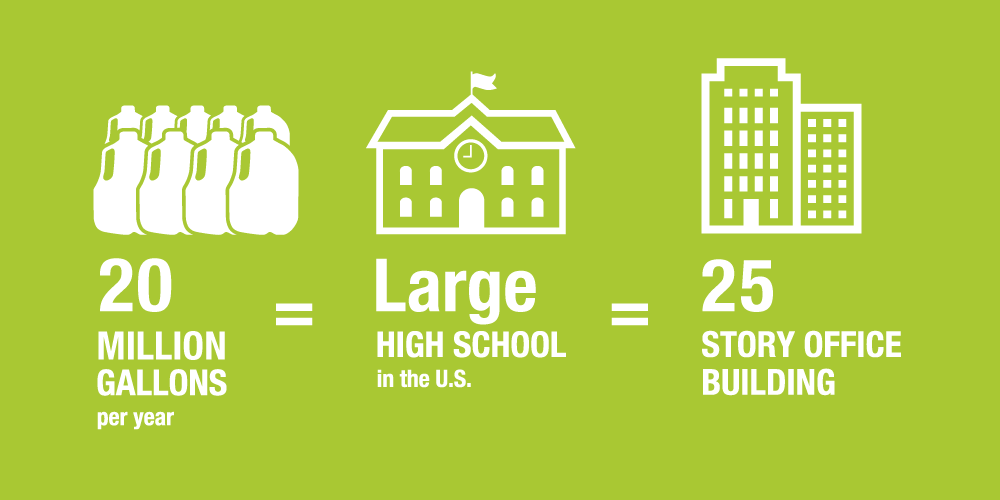

Water Usage

Greenbrier uses approximately 20 million gallons per year per manufacturing facility. In contrast, a pulp and paper mill can regularly use 10 million gallons in a day.

As a responsible corporate citizen, we demonstrate our values through charitable giving. Greenbrier also employs a diversity, equity and inclusion lens to our charitable giving.

Our targeted focus areas include:

Charitable Giving

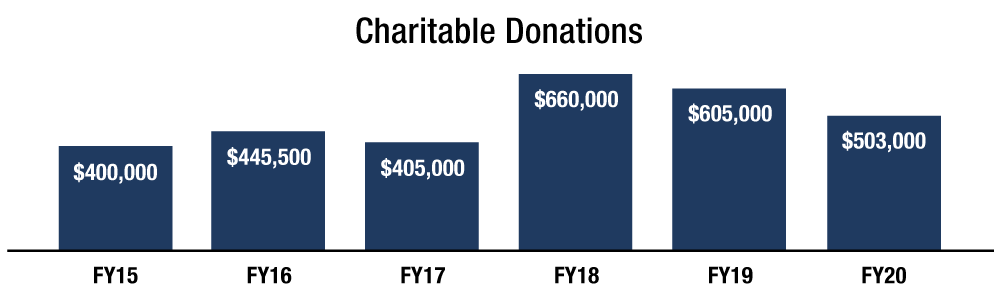

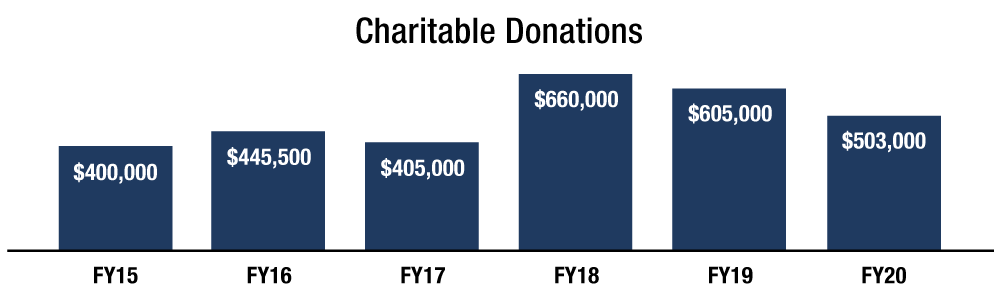

In 2019 we donated more than $605,000 in charitable contributions, and in 2020 we donated $503,000. Part of the decline in our year-over-year charitable giving totals was due to an expected downturn in the freight rail industry. Coupled with COVID-19, Greenbrier—among many other organizations—became cautious about expenses, but we remain focused on impactful philanthropy. As we move past the challenging business environment presented in 2020, we will increase our levels to pre-economic downturn levels.

Our Goals:

As we move forward in our philanthropic efforts, we intend to:

• Allocate over 50% of our annual charitable contributions to underserved communities that align with our IDEAL goals by 2022.

• Channel at least 25% of all of Greenbrier’s philanthropic giving to diversity scholarships by 2023.

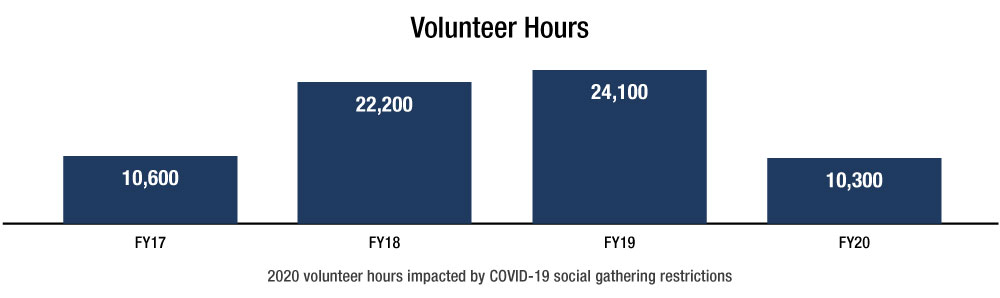

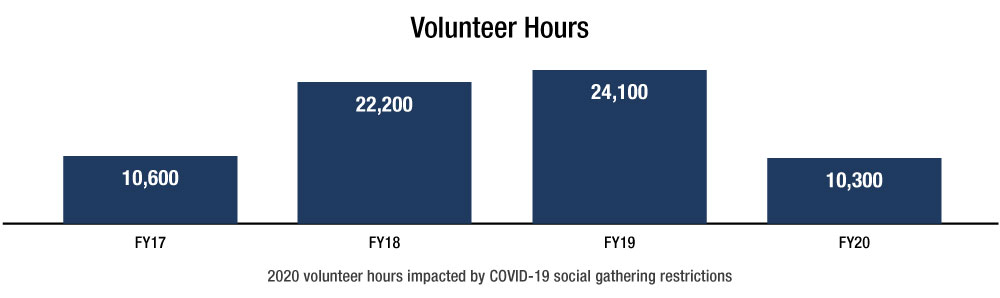

Employee Volunteerism

Our global volunteer hours have consistently increased

since we began tracking this metric in 2017. We expect to

maintain this trend as the impacts of COVID-19 recede.

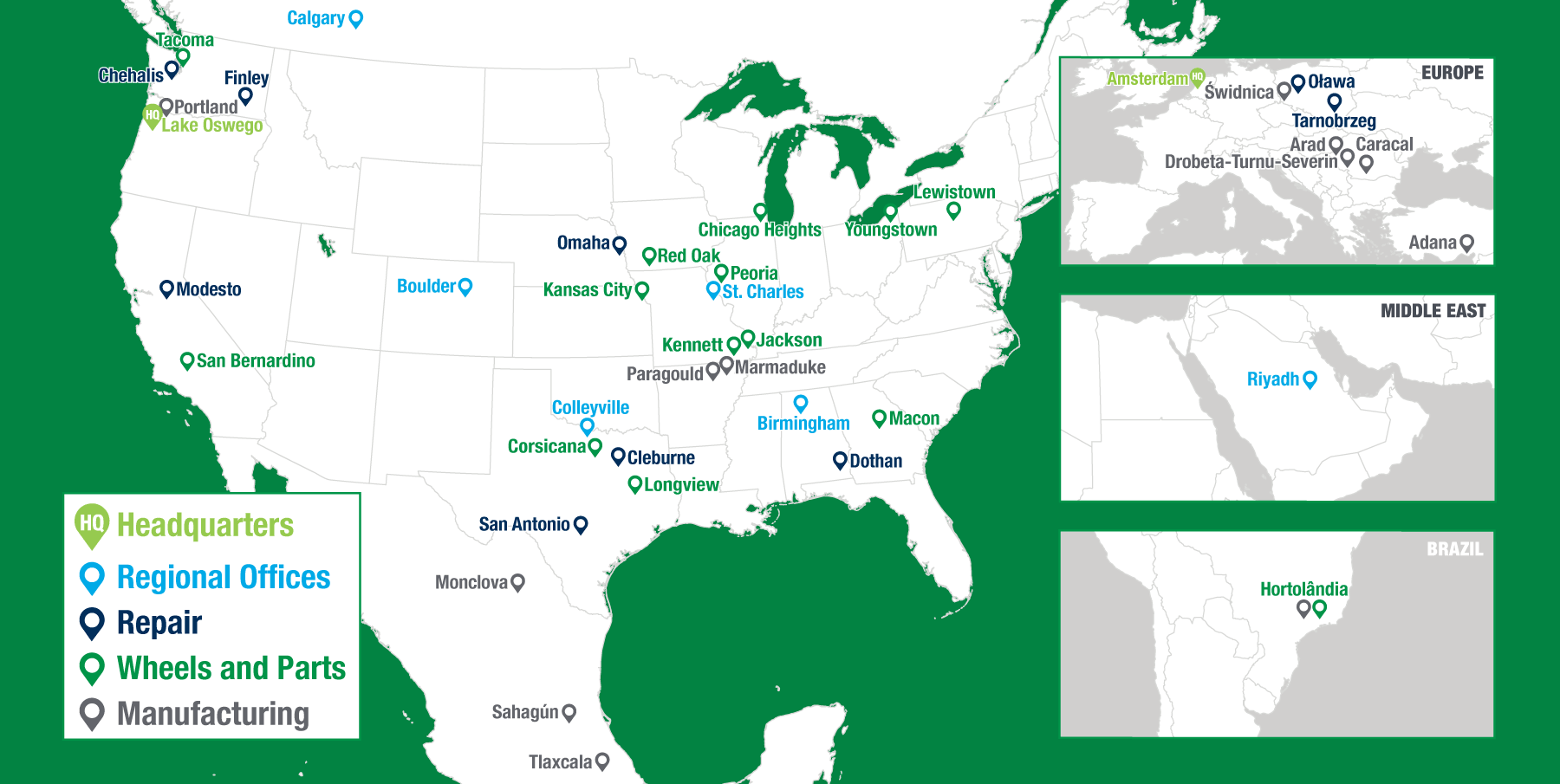

Where We Are

Going forward, Greenbrier maintains its focus on continuous improvement in our operations, our resource utilization and our awareness of the needs of the people who work for us and live in our communities.

SASB Index

| TOPIC |

METRIC |

CATEGORY |

UNIT OF MEASURE |

SASB CODE |

RESPONSE/COMMENT |

| Accounting Metrics |

Number of units produced by product category |

Quantitative |

Number |

RT-IG-000.A |

Greenbrier’s annual production mix can vary widely across product type and manufacturing volume. During FY21, Greenbrier will develop a standard methodology of this activity as it relates to energy use, GHG emissions and materials consumption.

Sales data is provided in Greenbrier’s annual report to shareholders on Form 10-K. |

| Number of employees |

Quantitative |

Number |

RT-IG-000.B |

10,589 |

| Energy Management |

Total energy consumed |

Quantitative |

Gigajoules (GJ), Percentage (%) |

RT-IG-130a.1 |

FY20: 1,644,720 Gigajoules (GJ) total energy usage.

Electricity usage tracked in Megawatt Hours, converts to 668,650 GJ. Onsite fuel use is tracked and is 976,070 GJ. |

| Percentage grid electricity |

40.6% |

| Percentage renewable |

Not tracked separately |

| Employee Health & Safety |

Total recordable incident rate (TRIR) |

Quantitative |

Rate |

RT-IG-320a.1 |

FY19 IR was 1.75

FY20 IR is 1.59

FY19 DART Rate was 1.36

FY20 DART Rate is 1.29 |

| Fatality rate |

0.000 in FY 2020

0.0053 in FY 2019 (1 employee, FY19) |

| Near miss frequency rate (NMFR) |

FY20: 23.69

Greenbrier emphasizes the importance of reviewing all work-related environmental, health and safety incidents, including near misses. |

| Fuel Economy & Emissions in Use-Phase |

Sales-weighted fleet fuel efficiency for medium- and heavy-duty vehicles |

Quantitative |

Gallons per 1,000 miles |

RT-IG-410a.1 |

Not applicable to Greenbrier |

| Sales-weighted fuel efficiency for non-road equipment |

Quantitative |

Gallons per hour |

RT-IG-410a.2 |

Greenbrier does not make equipment with engines for transportation purposes and the fuel efficiency does not apply. Given the diversity of our products and applications in which our products are used, as well as the lack of industry standards to estimate on a per unit of work basis, Greenbrier does not calculate sales-weighted fuel efficiency or emissions in this manner. |

| Sales-weighted fuel efficiency for stationary generators |

Quantitative |

Watts per gallon |

RT-IG-410a.3 |

Sales-weighted emissions of:

(1) nitrogen oxides (NOx) and

(2) particulate matter (PM) for:

(a) marine diesel engines,

(b) locomotive diesel engines,

(c) on-road medium- and heavy-duty engines, and

(d) other non-road diesel engines |

Quantitative |

Grams per kilowatt-hour |

RT-IG-410a.4 |

| Materials Sourcing |

Description of the management of risks associated with the use of critical materials |

Discussion and Analysis |

N/A |

RT-IG-440a.1 |

Greenbrier responsibly sources the raw materials used to build our products. |

| Remanufacturing Design & Services |

Revenue from remanufactured products and remanufacturing services |

Quantitative |

Reporting Currency |

RT-IG-440b.1 |

Our Wheels, Repair and Parts business generated 12% of Greenbrier’s FY20 annual revenue and relies heavily on remanufactured and scrap steel materials. |